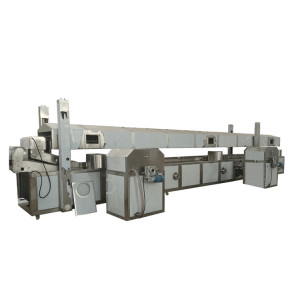

Full Automatic Potato Chips Making Machine

- Model

- Full Automatic Potato Chips Making Machine

Review

Description

Potato Chips Making Machine

1.full automatic fresh potato chips making machine price project

Fresh potato chips is more and more popolar in snacks industrial because of it's healthy and nutrious. It is made of potato: peel,cut,fry,flavor,pack.

We are the professional manufacturer of the full automatic potato chips machine, basiced on customers demands, we designed top quality whole line solution for satifying different capacity demands: 10-1000kg/h.

full automatic potato chips making process:

washing and peeling machine-cutting machine-washing machine-blanching machine-frying machine-flavoring machine-packing machine.

2.ull automatic potato chips specification

| No. | Machine Name | Function | Power | Others |

| 1 | Peeling Machine | Remove the potato peel | 1.5kw | / |

| 2 | Cutting Machine | Cut potato into slices | 0.75kw | / |

| 3 | Washing Machine | Remove starch | 1.5kw | / |

| 4 | Blanching Machine | Protect color | 1.5kw | / |

| 5 | Frying Machine | Fry potato chips | 10kw | / |

| 6 | Flavoring Machine | Make different flavors as demands | 0.5kw | / |

| 7 | Packing Machine | Pack potato chips into bag | 8kw | / |

| 8 | Nitrogen maker | Fill Nitrogen to bag | 5kw | / |

3.full automatic potato chips making machine price pictures:

1)Small capacity potato chips making machine price line:

10-30kg/h, 30-50kg/hm, 50-80kg/h,100kg/h

2)Big capacity lines for potato chips making machine price:

200kg/h,300kg/h,500kg/h,1000kg/h......

Our packaging and shipping

1.Pacaking:

All machines which need pacaged will be covered by film then put into the export standard wooden case, use the cystosepiment to prent breaking on ship.

The wooden case will be fixed inside the container tightly by the rope.

Export standard wooden case will be palleted for easy unloading for customers.

2.Shippping

We select the direct ship for sending the machines to customers within shortest time as we can. And all main BL for ensuring the safety of the machines.

We update the shipping information to customer in time.

Our 300kg/h full automatic fresh potato chips making machine services:

1.Pre-sale service:

We supply proposal and quotation to customers as demands, invitate customer come to check our machines quality.

2.After-sale service:

1 year free warranty, after 1 year, life time warranty with basic cost.

Overseas installation,training and testing.

Basic spare part service

Zhucheng Xinxudong Machinery Co., Ltd. was established in 1999. We are the pioneer in manufacturing a variety of food production line machinery. Currently our business group is comprised of three companies, each an industry leader in its own food production line category.

Zhucheng Xinxudong Machinery Co., Ltd is specialized in frying lines and the production lines of fresh potato chips and frozen French fries. We have a strong R&D team that consists of more than 10 outstanding engineers, and an extensive sales team with more than 50 sales/service staff to assist our clients from all over China.

Our certificates:

ISO,CE,ALIBABA ASSESSTED SUPPLIER,CSA,UL,SGS:

We can supply certificates as customers damands for importing items.

BRAND-TCA

COMPAMY NAME:ZHUCHENG XINXUDONG MACHINERY CO.,LTD

Currently we are receiving more and more requests from abroad as the quality of our machines and our competitive pricing have been recognized by clients from all over the world. We are also highly recommended by our clients due to our devotion to provide the highest standard after-sales services. So far our machines have been exported to many nations such as the USA, the UK, Germany, Italy, Spain, Saudi Arabia, Algeria, the Philippines, Malaysia, Indonesia, India, Italy, Australia, Pakistan and more......

4.Our chips solution catalogue:

1)Potato chips processing line

2)Banana/plantain chips processing line

3)Sweet potato chips making line

4)Cassava chips processing line

5)Others chips solution

Our main products catalogue:

1)Frying solution

2)Potato solution: frozen french fries production line,potato chips

production line

3)IQF tunnel quick freezer

4)Frozen vegetables processing line

5)Chicken nuggets/burger patty processing line

6)Dumpling making line