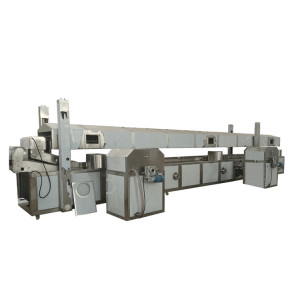

Automatic French fries line manufacturer frozen fries production line

Review

Description

China Automatic Professional Fresh Potato French Fries Making Machine for frozen fries

Automtatic A complete line For Potato French fries machine is a complete line from washing peeling to the freezer and packing.

1. Requirement for fresh potato

Oval in shape;

Fry material content≥20%;

Sugar content≤0.2%;

Color outside is yellow

Color inside is white

Size is 8*8, 10*10, 12*12mm

2.Frozen French fries process

Potato Washing -- peeling—cutter—washing—blanching—dewater machine—drying line--pre-fry—deoil machine—cooling line--freezed--packed --store in cold room

3. Capacity

It is 2:1 for fresh potato and frozen French fries

For zsemi-automatic line: it is 50-150kg/h

Automatic line: 100-150kg/h, 200-250kg/h, 300kg/h, 500kg/h, 800-1000kg/h,

Main Features

1) a complete line from A to Z

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) Good experience for this line

4) All is SUS304

5) Good service

The details for the processing line:

Peeling process

Two process: Brush washing and stone brush peeling

It can wash off the stone and sands and also can remove some skin of the fresh potato. With the help of the stone brusher, the fresh potato can be completely removed

Bubble washing machine

Washing process is for washing off the potato starch on the potato chips which can keep it from fall in the oil and keep long-use life for the frying machine.

At the same time, the potato chips is totally immersed in water which can keep it from enzymatic-oxydative browning, because the sugar can be affected with amino acid and the produce the black and brown color

Made of SUS304

Blanching machine

Blanching process: Blanching is a necessary procedure. After washing, the potato sticks go into the blanching machine which is about 65-90 ℃ hot water. It can destroy the enzyme activity, and improve and soften the organizational structure which can be easily dried and also can keep from blistering. It can add the Sodium hydrogen sulfite or Sodium pyrosulfite to keep good color.

Made of SUS304

Frying machine

Frying process

The frying time is 2-3minutes at the frying temperature is 170-180 ℃

Frying oil:

choose oil not easy to be oxidative rancidity and of high stability, such as rice oil, palm oil, hydrogenated oil. The rice oil and colza oil are liquid oil and of big oil smell. The palm oil is solid oil which is mild. Hydrogenated oil is of cream flavor.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.